Ammonia in research projects – challenges and learning points from the AEGIR project

On 14 February, the project participants in the AEGIR project under the Nordic Maritime Transport and Energy Research Programme organized an online seminar to look into the challenges and learning…

On 14 February, the project participants in the AEGIR project under the Nordic Maritime Transport and Energy Research Programme organized an online seminar to look into the challenges and learning points they had experienced and gained from the project.

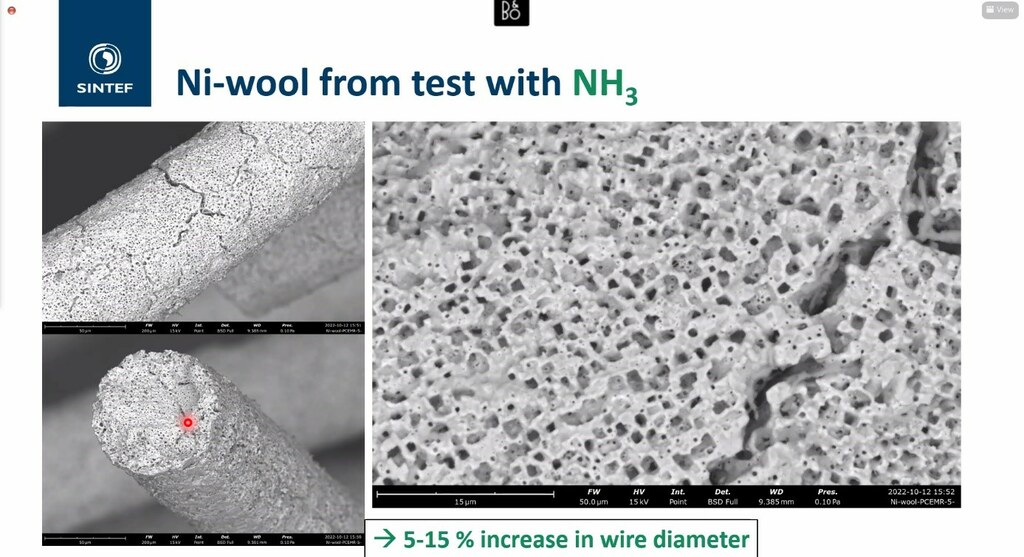

The seminar shared experiences of the three research groups from DTU and SINTEF, who installed ammonia in their research facilities to investigate ammonia related aspects for tests of solid oxide fuel cell (SOFC), a proton conducting electrochemical membrane reactor (PCEMR), and a polymer exchange membrane fuel cell (PEMFC).

Key topics were corroding metals, safety assessments, and ensuring safe handling of ammonia gas. The presentations span over the use of pure ammonia as fuel up to trace amounts of ammonia in hydrogen, covering equipment, components, and safety.

Ammonia is a promising fuel alternative that has the potential to be zero-emission if produced using renewable energy. Ammonia is easier to liquefy than hydrogen and contains 70% more energy per volume compared to liquid hydrogen, making it an attractive fuel especially for large, ocean-going ships. Furthermore, as ammonia is widely used as a fertilizer, an infrastructure for safe transport and handling is already in place worldwide. On the other hand, ammonia poses challenges towards safety and handling in research environments that differ from the large scale handling.

The online seminar had over 30 participants.

The AEGIR project aims at developing an ammonia-fuelled ship propulsion system that offers high efficiency in combination with a low total system volume and weight, all whilst avoiding emissions of NOx and the reducing CO2 emissions.

Presentations from the seminar will be accessible shortly.

For more information about the project results, contact Anke Hagen.